VRF(S) Special machines

‘DryAir’ Dehumidification

Desiccant Dryair provides solutions to air quality, for companies where dehumidification is an essential, and often critical part of everyday production processes.

Our dehumidifiers can maintain relative humidity as low as 1% (VRF(S) series only) at a constant level, regardless of the ambient conditions, they can be employed in many industrial and commercial applications.

Features of our ‘DryAir’ Dehumidifiers

- Lower footprint/weight per cmh

- Capacities from 75 m3/Hr to 100 000 m3/Hr as standard.

- A unique triple point control on all machines over 750 m3/Hr, measuring the regeneration temperature onto the wheel, the wheel off temperature (wet air) and the RH or Dew point of the air being dried. This combination ensures the amount of energy input is relevant to the moisture being extracted.

- Numerous options available, pre-heaters and coolers, post heaters and coolers, humidifiers and many other variations.

- Filters up to F8 as standard with HEPPA & ULPA available.

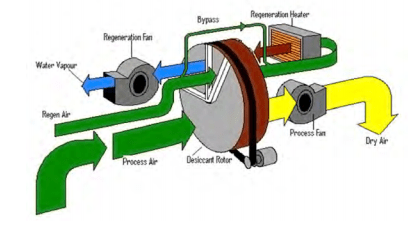

- Highly efficient Silica Gel Rotor for efficiency & durability, high moisture removal efficiency

with the lowest energy costs. - PTC electric heaters for regeneration.

At Desiccant DryAir our attitude is solutions not compromise, every VRF special is created to work within the customer’s unique circumstances to overcome their particular HVAC problems. Where other manufacturers can only offer a production line solution that may cost more in production and running costs, we will create you a machine designed specifically for your needs.

This can include innovative design to overcome issues such as;

• space restrictions

• power & economical issues

• ambient heat & air quality problems

• environmental, green & carbon footprint concerns

• environment sterility

and many more.

Our skills and knowledge in manufacturing these machines is unsurpassed, using 3D CAD design at every stage of development we can track and change each nut and bolt, each rivet, every bend and fold to ensure a finished product of superior quality.

The VRF(S) range are the embodiment of many years experience in;

• AutoCAD 3 dimensional product design

• Stainless steel fabrication, folding, cutting and welding

• the latest refrigeration technology

• High pressure steam and gas implementation

• State of the art electronic control & monitoring

• Building Management Systems (BMS)

• Ducting, filtration and airflow systems

We are rightly proud of our product and some would say, smugly so. But so would you, in our shoes. But don’t just take our word for it – ask around, there are many satisfied businesses around the globe that are benefitting from our VRF(s) technology in their every day production process. Just call us for a chat about your dehumidification needs and we will prove to you why we are one the premier manufacturers of bespoke desiccant technology in the world today.

VRF(s) Special Range – Applications

Read More...

There are wide and varied uses for Controlled Humidity Environments spanning across the whole gamut of human activities, from manufacturing to domestic, farming to museums. We have produced an informative guide called ‘CHE an explanation’ which details how the concept works – it can be downloaded from our website. These are some typical applications for our medium size dehumidifiers;

Military Storage – for the last 30 years desiccant dehumidifiers have been used to protect valuable military equipment from corrosion and degradation, allowing aircraft, ships, tanks, weapons and ordnance to be maintained in an operational and ready state.

Food Industry – many food and confectionary businesses are realising the advantages of using desiccant dehumidification in their production process. Some of the main uses are;

Fish – by drying the surface of the fish, moisture loss during the smoking process can be prevented.

Confectionary – high humidity can cause problems such as chocolate blooming, stickiness in high boil products, caking of the product in hoppers and pipes and the product sticking together in the packaging process.

Sugar – low relative humidity is essential in the sugar industry to keep the product flowing freely. Sugar absorbs moisture causing it to become lumpy and hard. In this process, dry air is usually introduced into the ullage space of the storage silo.

Cheese – both temperature & humidity control are vital in the maturing stage of cheese manufacture.

Pharmaceutical Industry – desiccant dehumidification is the best choice where cross contamination is to be prevented. Desiccant rotors are non-toxic and bacteriostatic. Some of the uses are;

Tablets – prevents agglomeration, moisture uptake and crumbling of the product.

Coating – many products are coated in a water based product, which has to be dried quickly to prevent moisture from affecting the product.

Gelatine Capsules – hygroscopic materials such as gelatine need moisture protection prior to the capsule being sealed.

Packaging – low humidity is required during the packaging process to prevent effervescent tablets from dissolving and gelatine capsules from becoming sticky.

Media Storage: for the storage of sensitive video, photographic & audio media. Ongoing research means sensitive media can now be preserved for longer periods and held in temp/humid controlled vaults to provide the best & safest storage available.

Timber Drying: our machines can be used for the drying and storage of timber. Stage drying to prevent warping and shrinkage of the timber. CHE can equally be used to dry out buildings & historical items after flood or restoration.

Powder manufacturer: dehumidifiers can used to provide product stability & a suitable environment for the production and packaging of modern dishwasher & washing powders. Recent changes have been made to the packaging material, using a soluble film means less waste & safer product handling but this needs a CHE when being manufactured & packed.

Contact Us

Today!

Desiccant DryAir Systems Ltd.

6 Langdale Business Park

Whitegate White Lund Industrial Estate

Morecambe

Lancashire

United Kingdom

LA3 3BS

Contact us

Phone: (+44) 01524 581500

Alternative phone: (+44) 01524 581450

Mail: info@desiccantdryair.com

© 1996-2020 DESICCANT DRYAIR | LEGAL DOCUMENTS | SITEMAP

phone: (+44) 01524 581500

alternative phone: (+44) 01524 581450

info@desiccantdryair.com

Web Design By NCB Digital