Battery Management System

Battery Management in Military

Read More -

Desiccant Dryair usually provide solutions for air quality & dehumidification and this product was developed as part of a much larger ‘Vehicle Storage’ issue and was designed to be a total solution for the long term storage (in battle readiness) of military vehicles for the army in a Far East country.

The whole system is designed to:

- keep the vehicle electronics in a state of readiness for immediate action if required.

- dehumidify the interior & exterior of the vehicle to prevent corrosion over a long period of storage.

- extract engine fumes from the building

- during routine engine testing which has to be performed periodically.

Battery Management System and its features

Any type of battery capable:

- Lead Acid

- Wet Lead Acid

- VRLA inc. Armasafe series

- AGM

- Gel

- Silver / Calcium

- Calcium

Battery type is selectable through the software and charging algorithms are preloaded according to the battery.

Four Stage Charge

- Bulk Charge

- Absorption Charge

- Float Charge (or trickle charge)

- Storage Charge (to keep the electrolyte at it’s optimum condition)

Discharge Mode to determine the battery status and condition.

Auto Voltage Detection.

Zero to ten amp charging capability

Battery Management System benefits

Accessibility

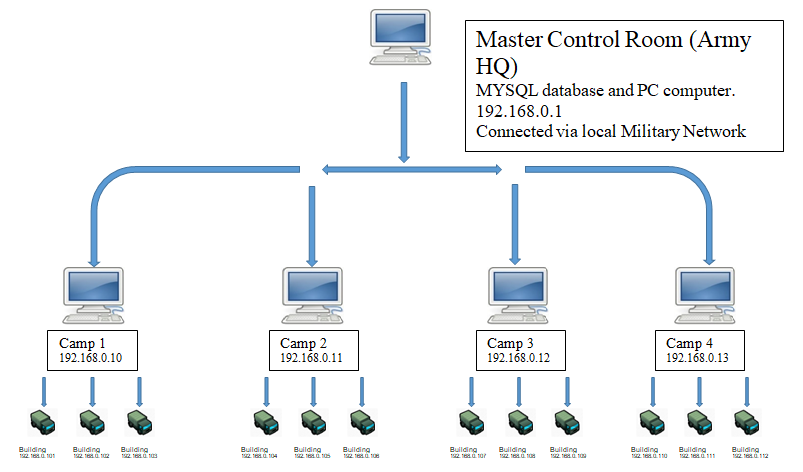

One of the criteria that this system had to fulfil was that the feedback from the charging unit and attached batteries had to be accessible from any PC or Mac and from any location worldwide, via the internet. The user would also need the ability to edit the information and make adjustments to the system either in performance or function settings. This meant we had to create a special software package based around PLC programming that would constantly, and in real time, update itself. An administrator or any other designated personnel listed in the system would login to the software via the internet. Each person would also have tiered access, in other words, each user had access only to the areas that the administrator would allow. This means that an engineer cannot access and change settings made by the software writer and the building administrator cannot access changes made by the HVAC engineer, thus creating an environment whereby only the experts in their field were making the informed changes needed and nobody else could overwrite or alter this except the overall system administrator.

This functionality is unique to the client and their particular requirements and the system is set up for the client’s personal needs, circumstances, environment and hierarchy.

Fault Detection Functionality

From the outset, this client demanded extended features and functions from this system. One of these was a fault detection and reporting ability above and beyond any other competitor’s system. We achieved this by incorporating ground-breaking technology and electronics knowledge from across the globe. Our charger is capable of identifying issues and faults that no other system can. These can include: detecting low fluid levels within an individual connected battery; our discharge program can ascertain when an individual battery was last charged and the status of that charge; battery failure prediction software is incorporated in our system whereby a warning is generated for the user informing of impending battery or charge failure. It is innovations such as these that put our system out in front of the competition.

System Status Information Display

In terms of finance and personnel we had to invest heavily in creating the software and programming that would provide the user with important information above and beyond the norm, paying particular attention to areas that our competitors either do not provide or have omitted. This includes; bulk, float, absorption and soak status displays, historic graph generation per battery charge, vehicle type and charging history for that vehicle, alarm displays for charge and discharge programs and cloning facilities for battery & vehicle types.

Once again it was this attention to information detail and the technological requirements of the client that won us the contract to manufacture and install this intelligent system.

Multiple Battery Version Capability

Our system has been developed specifically with expansion included. Currently the system is being utilised for vehicles only but we decided that to achieve maximum expansability we should program into our design the capability to charge and monitor other battery types other than the client was initially requiring. Our system can be adapted into many other industrial or civilian areas such as aviation and marine products.

Currently we can charge and monitor several industrial standard battery types such as Lead Acid – Wet Lead – AcidVRLA inc. Armasafe series – AGM – Gel – Silver / Calcium & Calcium / Calcium.

Battery charging basics & charging algorithm fundamentals

Introductory Note

Methods of charging lead acid batteries will be explored at a very fundamental level. Many manufacturers make a wide range of battery chargers that work just fine with a particular type of battery, when used in a specific application. There are few chargers, if any, that work very well with all types of lead acid batteries in all types of applications.

What happens to a battery when it is charged and discharged

The chemical reactions on discharge convert lead, lead oxides, and acid into free electrons, water, and lead sulphates. The chemical reactions on recharge reverse the process. The tricky part is to recharge the battery in such a manner so that the sulphates are eliminated by recombining with water to re-form into acid without losing the hydrogen and oxygen gasses that make up the water.

Oxygen and hydrogen gas will be released at recharge voltages between 13.8 V (2.30 volts per cell) and 14.2 V (2.37 vpc). You will see later that virtually all battery chargers have output voltages during some portion of the charge algorithm that are higher than the gassing voltage. Battery construction plays a very large part in determining what happens to the oxygen and hydrogen gas after it is released as a by-product of the recharge chemical reaction.

What is a charge algorithm

The battery charger controls the voltage that is applied to the battery, the amount of charge current that is supplied to the battery, and depending on the level of sophistication in the charger technology, the timing associated with what may be multiple voltage and current levels. The following paragraphs provide an overview with some significant detail of the different charging modes, or stages that may be included in a charging algorithm. Basically, a charge algorithm is a collection of all of the software controls over electrical parameters and timing that are applied sequentially to the charging system hardware for the express purpose of recharging a discharged battery. Stated a little more directly, the charging algorithm is what controls the battery charger behaviour as measured at its electrical output terminals.

Without some type of battery or charger malfunction, the only way that the battery voltage can go down below the charger output voltage is if the battery is connected to an external load that draws current from the battery. As the battery delivers current, its charge capacity decreases and its voltage drops. When the battery charger is connected to the battery while the battery is under load, and if the load current is large enough, then the charger current is diverted to the load.

As long as they are functioning properly, our system can be left connected to the battery indefinitely.

The obvious question is: “What happens if the charger is not functioning properly and it is left connected to a battery?” Batteries store a tremendous amount of energy due to their electrochemical composition. As that energy is transferred out of the battery into a load (discharging) and into the battery from a charger (charging), there are some risks involved. The basic chemical reaction occurs between the conductive lead grid, the various oxides and active materials, and the sulphuric acid, which is the electrolyte. Depending on the reaction rates, the sulphuric acid will decompose into gaseous components. The biggest danger to a battery is water loss, ultimately resulting from the escape of hydrogen and oxygen gasses during recharge. The importance of charging voltage values applied to a battery, and the reason that several manufacturers recommend different charging voltages, is the effect that the charging voltage has on the acid decomposition into gas, or just simply “gassing”. The more gas that is generated, the more water that is lost, the quicker the battery dries out, and ultimately wears out.

Now back to the original question. If a battery charger fails during continuous float maintenance mode such that its output charging voltage is higher than the minimum gassing voltage of the battery, the battery will expel gas and dry out. The other danger is that any mixture of hydrogen and oxygen containing more than 4% hydrogen is potentially explosive. Therefore it is very important to periodically monitor the battery to make sure that there is not a problem. Also, the battery should be recharged in an open area with good ventilation, away from any sources of sparks or combustion, like water heaters and electrical motors.

Vertical Rotor Face Machines

We have a range of Vertical Rotor Face Machines (VRF) available, find the right machine to suit your needs. if you require help or advice please contact us by calling us on +44 01524 581500 or email us info@desiccantdryair.com

MTHC Units

We have a range of Medium Temperature & Humidity Control Units (MTHCU) available, find the right unit to suit your needs. if you require help or advice please contact us by calling us on +44 01524 581500 or email us info@desiccantdryair.com

Contact Us

Today!

Desiccant DryAir Systems Ltd.

6 Langdale Business Park

Whitegate White Lund Industrial Estate

Morecambe

Lancashire

United Kingdom

LA3 3BS

Contact us

Phone: (+44) 01524 581500

Alternative phone: (+44) 01524 581450

Mail: info@desiccantdryair.com

© 1996-2020 DESICCANT DRYAIR | LEGAL DOCUMENTS | SITEMAP

phone: (+44) 01524 581500

alternative phone: (+44) 01524 581450

info@desiccantdryair.com

Web Design By NCB Digital